There are many logistics companies in North Carolina that can help you, whether your company requires a warehouse, distribution center or product transport. They can provide many services, including warehouse distribution and drayage trucking.

North Carolina's Charlotte region can provide distribution services. It is conveniently located between two major interstate highways, and offers easy access to large parts of the U.S. population as well as ports. It is also the home of the sixth busiest international airport in the country.

Charlotte also offers many benefits to companies that want to operate their distribution centers there. You will have easy access from major ports as well as a convenient location within the inland city. There is also plenty of industrial space available that's affordable. The nation's best high-tech research facility is located in the area.

North Carolina continues to invest in its rail infrastructure. The state actually has the most extensive consolidated rail system in America. The rail network serves 22 states. This means your company will be able to reach more than 70% in the United States within a matter of hours.

North Carolina also has two major shipping points. Port of Wilmington (morehead city) offers full-service transportation to both coast and inland areas. The Port of Virginia is also accessible at Norfolk/Hampton Roads.

There are many major aerospace companies in North Carolina, along with many other manufacturers. North Carolina also boasts several Foreign Trade Zones. These zones make it a great place to either import or export products. Strong product demand is a result of a robust economy. This will have an effect on the global supply chain.

ACI Transport prides itself on its ability to adapt and be trustworthy. It also focuses on customer service and communication. ACI provides a wide variety of transportation services to the chemical, healthcare, and building industries.

C&O Warehousing & Logistics has a 400,000 square-foot modern warehouse facility in Raleigh-Durham, NC. The company offers complete distribution solutions, and is built around modern warehouse space.

The company's expansion is underway to better service the East Coast life science industry. A major Food & Beverage company is also a partner of the company. Over the next few year, 300 new employees will be added to the company.

CSX just opened the CSX Carolina Connector in Rocky Mount NC. It is an intermodal terminal. This project earned the company the Hay Award for Excellence. CSX is also launching direct rail service between the Port and Wilmington. This is a major boon to manufacturers in Rocky Mount, NC.

North Carolina is home to two full-service shipping ports. Port City Logistics offers a wide range of transportation services such as drayage trucking or warehouse distribution. Port City has 3.5 million square feet of warehouse space. Port City also offers brokered transportation solutions. Port City intends to invest $16 millions in a 150,000 sq. ft. building in New Hanover County. New Hanover County will be able to create 75 jobs with this new building.

FAQ

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. Knowing about manufacturing processes will help you understand how logistics works.

What skills are required to be a production manager?

Production planners must be flexible, organized, and able handle multiple tasks. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

What does it take to run a logistics business?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. You must be able analyze data and draw out conclusions. You need to be able work under pressure and manage stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

To meet tight deadlines, you must also be efficient and organized.

What is the role of a production manager?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure the quality of the product and service meets the client's requirements.

How can I learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. However, if that's not possible, you can always read books or watch educational videos.

What are the responsibilities of a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should be alert for any potential problems in the company and react accordingly.

They should also be able and comfortable communicating with other departments like sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

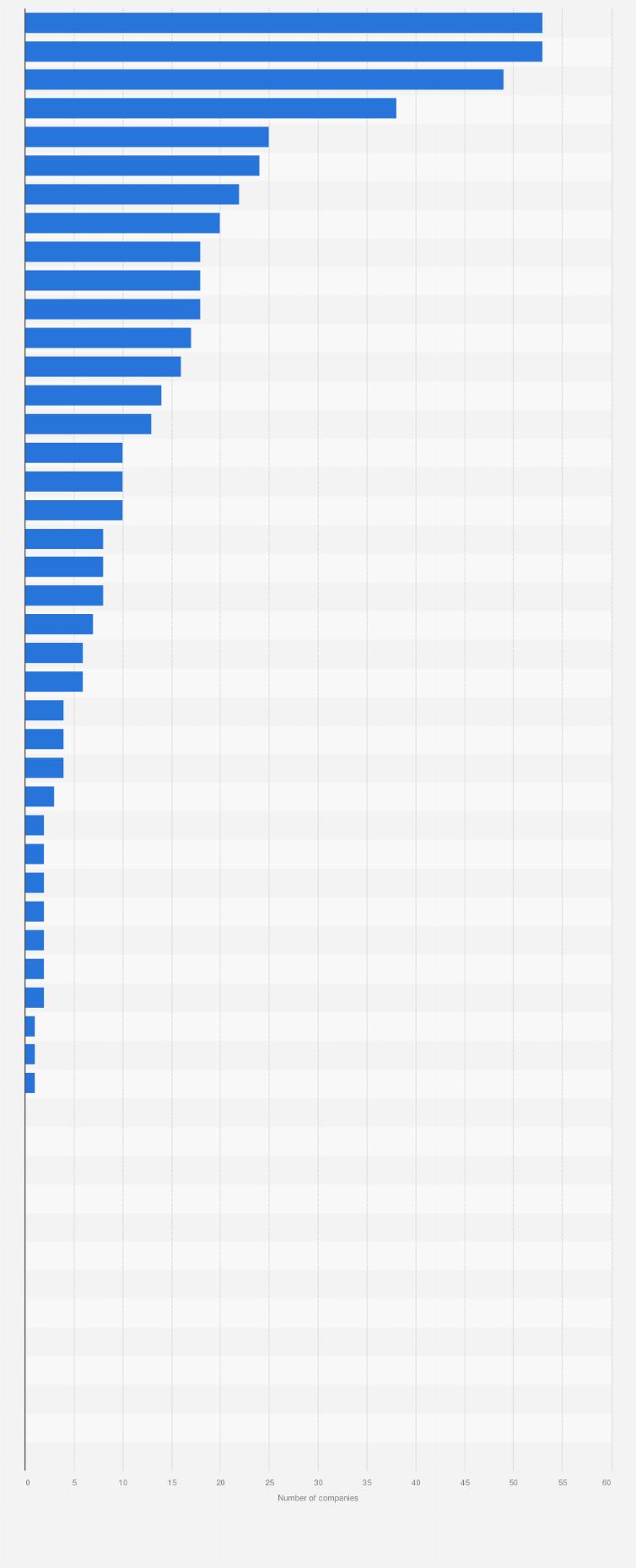

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's main objective is to reduce variations from the production average. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If you notice a large deviation, then it is time to fix it.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you understand that, it is time to identify the sources of variation. These variations can also be classified as random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. If you make widgets and some of them end up on the assembly line, then those are considered random variations. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

Once you've identified the problem areas you need to find solutions. You might need to change the way you work or completely redesign the process. After implementing the new changes, you should test them again to see if they worked. If they don't work, you will need to go back to the drawing boards and create a new plan.