As an industrial designer, you'll be responsible for the creation of innovative products for the home, office, and industry. In this article, you'll learn about Job duties, the Education and training you'll need, and the salary you can expect. You'll also learn how to get started and the different career options. This course will help you understand the advantages of this job as well as its potential for advancement. You'll be well-prepared for a rewarding career in design once you have completed your education.

Duties of the job

The Industrial Designer works with business, art, and engineering skills to create new products or services. They must ensure that brand strategies are aligned with their designs. A portfolio of successful industrial designers must be well-rounded and have experience in the field. Industrial Designers should have strong computer-aided designing software skills and creativity in incorporating new technology into products.

Industrial Designers, as part and parcel of their work, are responsible for the development of design concepts and regulations. They must be analytically and problem-solving savvy and be able effectively communicate design concepts across functional teams. They should be able work with engineers and create CAD models. Industrial Designers will need to be proficient not only in computer-aided designing software but also in Microsoft Office, Solidworks, Keyshot and Keyshot.

Education is necessary

If you are looking for a job in this field, it is helpful to have an education in an industrial design program. Students in such programs have the chance to build an electronic portfolio to show their design skills. Some industrial designers also hold a Master of Business Administration degree. This gives them the ability to enhance their business acumen, and helps them understand product limitations. Industrial designers apply their analytical skills to understand customer needs and reason to invent new products and services.

The type of job you want to be an industrial designer will determine the education needed. Industrial designers require at least a bachelor's level of education. Some schools offer degrees for industrial design. But others do not. In addition to business and design courses, candidates should also take courses in mathematics, computer science, engineering, art, and computer studies. A portfolio is also helpful to prospective employers. You have many opportunities for career growth and advancement, as there are with all jobs in design.

Opportunities for career advancement

There are many entry-level positions available in design firms, manufacturing companies and in-house design departments if your goal is to become an industrial designer. Next, you could apply for a job as a chief or design department head. No matter what position you choose, it is important to use your design skills wherever possible. Here are some common entry-level roles for industrial designers.

An industrial designer usually has a bachelor's degree or related qualifications, and many employers look for candidates who have a background in graphics or sketching, as these skills can enhance their applications for jobs. Employers may choose to hire candidates who are proficient in 3D modeling or CADD. An example: If you are an architect or civil engineer, an industrial design will need to be proficient in drawing, rendering and presenting their work for decision-makers.

Salary

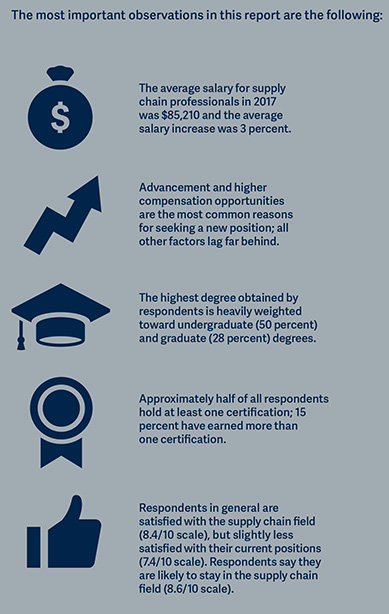

The annual salary of an industrial designer varies depending on the educational background and experience. In general, a person with a Masters degree or Doctorate degree earns more than $75,019 a year. A Bachelor's degree pays less. Industrial designers often move on to managerial positions. Here are some tips for increasing your salary. You should read carefully the job description to find out your exact salary expectations.

The average yearly salary for Industrial Designers is $62,315, but the actual amount may be much higher or lower. According to the U.S. Bureau of Labor Statistics, top earners in this field make $106,000 a year. However, it is important to note that this figure is just a starting point. Your experience, job location, and industry will affect your salary. After you have identified your skills and your location, you will want to examine the compensation for your industry.

FAQ

What is production planning?

Production Planning includes planning for all aspects related to production. This document is designed to make sure everything is ready for when you're ready to shoot. This document should also include information on how to get the best result on set. This includes information on shooting times, locations, cast lists and crew details.

It is important to first outline the type of film you would like to make. You may have already chosen the location you want, or there are locations or sets you prefer. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. If you decide you need a car and don't know what model to choose, this could be an example. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. Are you looking for people to sit in the front seats? Or maybe you just need someone to push the car around. Maybe you'd like to change the interior from black to a white color. These questions will help guide you in determining the ideal look and feel for your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Maybe you want to show the engine and the steering wheel. These things will help you to identify the car that you are looking for.

Once you have all the information, you are ready to create a plan. You can use a schedule to determine when and where you need it to be shot. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. This way, everyone knows what they need to do and when. You can also make sure to book extra staff in advance if you have to hire them. You should not hire anyone who doesn't show up because of your inaction.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects can be completed in a matter of days or weeks. Others may take several days. It is important to consider whether you require more than one photo per day when you create your schedule. Multiple shots at the same location can increase costs and make it more difficult to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budgeting is another important aspect of production planning. Setting a realistic budget is essential as it will allow you to work within your means. It is possible to reduce the budget at any time if you experience unexpected problems. However, you shouldn't overestimate the amount of money you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What is the role of a production manager?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. A production planner ensures that the service and product meet the client's expectations.

What are the responsibilities of a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They must also be able to communicate with sales and marketing departments.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

How can we improve manufacturing efficiency?

The first step is to identify the most important factors affecting production time. Next, we must find ways to improve those factors. You can start by identifying the most important factors that impact production time. Once you've identified them, try to find solutions for each of those factors.

What does warehouse refer to?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be indoors or out. Sometimes, it can be both an indoor and outdoor space.

Is automation important for manufacturing?

Automation is important not only for manufacturers but also for service providers. Automation allows them to deliver services quicker and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What is the importance of logistics in manufacturing?

Logistics are an integral part any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use the Just-In Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It allows you to get the right amount resources at the right time. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This way you won't be spending more on things that aren’t really needed.

There are many types of JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you predict the amount you can expect to sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT: This type of JIT is most commonly used. Here, you allocate certain resources based on demand. You might assign more people to help with orders if there are many. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's used when you want to maximize production while minimizing inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. It is essential because it reduces lead-times and increases throughput.