Maritime logistics jobs have a lot of opportunities for those who want to get into this industry. This is a highly specialized industry that requires a lot of training. This industry is highly specialized and requires a lot of training. You might want to visit websites such as Shiptalk or Hellenic Shipping News to learn more. It is a highly rewarding profession to be a part of.

The largest component of the maritime industry is bulk cargo. This includes general cargo ships (ore and coke carriers), tankers, container vessels, and tankers. In the past, the loading and unloading process took much longer than it does today. Because of this, average ships spent more time at dock than at sea. Technical improvements have made the process much more efficient. The shipping cost is kept low thanks to economies of scale.

As containerisation transformed freight routes, many new services were developed in late 1950s. This transformation has been made possible by several technologies, including global positioning systems and computer-aided navigation. Self-unloading ships, for example, are now possible. Although the shipping industry has experienced some recent declines, it is still a lucrative field to be a part of.

Similar to other industries there are many positions available in maritime logistics. For example, there is a need for logistics/embarkation specialists who are tasked with preparing supplies for embarkation. They might also be involved planning and executing force deployments. This is a complex role that requires a thorough understanding of the relevant technology.

A shipping representative is responsible for offering competitive pricing to the company and keeping its pricing information clean and current. This person also needs to contact airlines and co-loaders to obtain the best possible rates. He or she could also be responsible to organize company information for tenders. This position also requires a good knowledge of port areas.

As with any other industry, a maritime logistics job requires a thorough knowledge of a variety of subjects. This is largely due to the industry's global nature. This is further complicated by most vessels being owned by companies outside the United States. Sponsorship opportunities are very limited. You can research the industry on websites like Shiptalk and find marine logistics jobs. If you're interested in this career, an apprenticeship program might be worth your while. They are also available for military personnel. You will be awarded a certificate upon completion of the program and an industry-specific knowledge.

If you are looking for a rewarding career with a great salary and many perks, a position in maritime logistics may be the next step. Centerline Logistics, the largest provider of marine transportation services in the United States is looking for QMED/Oilers that have at least two years experience in marine fuels.

FAQ

How can efficiency in manufacturing be improved?

First, identify the factors that affect production time. We then need to figure out how to improve these variables. You can start by identifying the most important factors that impact production time. Once you identify them, look for solutions.

What are the responsibilities of a logistic manager?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

What is it like to manage a logistics company?

You need to have a lot of knowledge and skills to manage a successful logistic business. Effective communication skills are necessary to work with suppliers and clients. You should be able analyse data and draw inferences. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

You must be organized to meet tight deadlines.

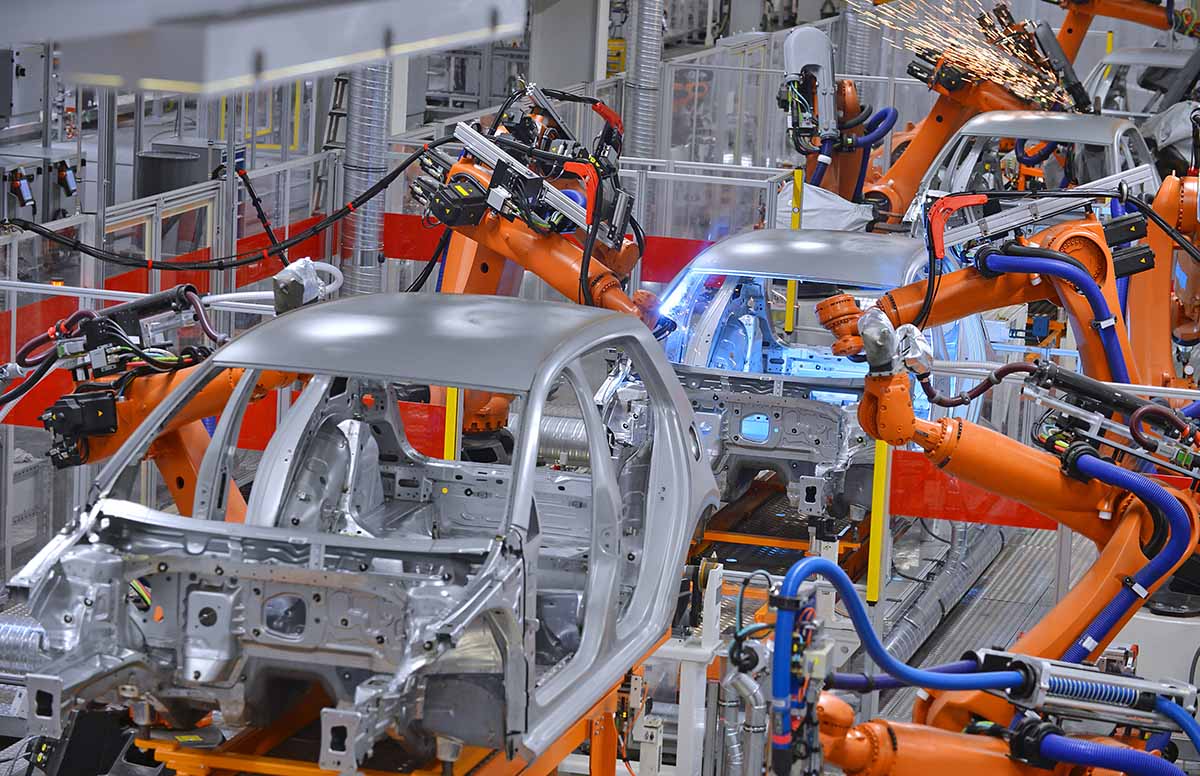

Can some manufacturing processes be automated?

Yes! Since ancient times, automation has been in existence. The Egyptians created the wheel thousands years ago. To help us build assembly lines, we now have robots.

Robotics is used in many manufacturing processes today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing can also be automated in many other ways. For instance, 3D printing allows us make custom products and not have to wait for months or even weeks to get them made.

How can overproduction in manufacturing be reduced?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time needed to manage inventory. By doing this, we could free up resources for other productive tasks.

This can be done by using a Kanban system. A Kanban board is a visual display used to track work in progress. Work items are moved through various states to reach their destination in a Kanban system. Each state is assigned a different priority.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows work to move forward and ensures that no work is missed. A Kanban board allows managers to monitor how much work is being completed at any given moment. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Waste includes anything that does not add value to the product. These are some of the most common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

How can manufacturing avoid production bottlenecks

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes planning to meet capacity requirements and quality control.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It focuses on eliminating variation and creating consistency in your work.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use the Just In-Time Production Method

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. This is where you have the right resources at the right time. This means that you only pay for what you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He noticed that workers were often paid overtime when they had to work late. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You will have the resources and people to solve any problems you anticipate. This way you won't be spending more on things that aren’t really needed.

There are several types of JIT techniques:

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow you to track how much material you have left over after using it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows for you to anticipate how much you can sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT : This is probably the most popular type of JIT. This is where you assign resources based upon demand. You will, for example, assign more staff to deal with large orders. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: This is another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based JIT : This is the newest type of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, your goal is to add value to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's used when you want to maximize production while minimizing inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important as it reduces leadtimes and increases throughput.