The industry offers many job opportunities for people who want to become nuclear engineers. Some of the roles include designing and building nuclear systems, developing nuclear equipment for power plants, and improving medical equipment. This industry is also responsible to decommission nuclear power plant.

Although nuclear engineers can earn a high salary, it is dependent on where you live. For example, in the United States, the average salary is around $106,060. You can expect a wide range of salaries depending on where you live and how many years of experience. The highest-paid nuclear engineers are paid over $143,000 per annum.

While the nuclear industry is known for being male-dominated, it does not necessarily mean that women cannot work within this sector. Many major corporations have been proactive in recruiting minorities and women.

There are many tasks that nuclear engineers have to perform, including the design of nuclear power plants, research into radiation's effects on humans, and overseeing radioactive waste disposal. They can also be involved in pilot projects or run nuclear power stations. For entry-level positions, a bachelor's degree is recommended in nuclear engineering. A master's degree in nuclear engineering may offer more opportunities to work in higher-ranking engineering positions.

Nuclear engineers need to keep up with the latest developments in the field, including the latest safety procedures, regulations, and laws. In addition, nuclear engineers must maintain their skills by attending annual training sessions. They could work a standard work schedule or may work overtime.

The most common jobs for nuclear engineers include working in power plants and universities. You may also find them in an office, or on a construction site. This job requires problem-solving skills as well as interpersonal skills and logical thinking. The nuclear engineers must also be able to maintain their calm under pressure. There is zero tolerance for mistakes. However, nuclear engineers must conduct thorough investigations whenever they make mistakes. They must then share their lessons with other engineers and present their findings to a review board.

The future is predicted to see a rise in demand for nuclear engineering professionals. According to the future, demand will rise in both medical and research areas as well as technical consultancy services. However, electric power generation demand will decline over the coming decade.

The highest pay for nuclear engineers is expected to be in the Professional, Scientific, and Technical Services category. A salary of up to $125,130 per year is possible. For nuclear engineers, the Occupational Employment Statistics (OES) Survey for Nuclear Engineers indicates that the median annual wage is around $120,380. You may also find a higher salary in some areas. California has the highest average salary for nuclear engineers at $152,620. Bolinas and San Francisco are the next highest.

A PhD in nuclear engineering will earn you between mid- and high-$150. These jobs are not as common, but they can be quite lucrative in the US. You can be a PhD nuclear engineer and serve in the US Navy as a professor at a nuclear power school or join a commercial nuclear power company.

FAQ

Why should you automate your warehouse?

Modern warehouses have become more dependent on automation. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses need to adapt quickly to meet changing needs. They must invest heavily in technology to do this. Automation warehouses can bring many benefits. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety enhancements

-

Eliminates bottlenecks

-

Companies can scale more easily

-

It makes workers more efficient

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

It reduces downtime, and increases uptime

-

High quality products delivered on-time

-

Removes human error

-

It ensures compliance with regulations

What is the difference between a production planner and a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. It is important to know about the manufacturing processes in order to understand how logistics works.

What are the logistics products?

Logistics involves the transportation of goods from point A and point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What is the job of a logistics manger?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

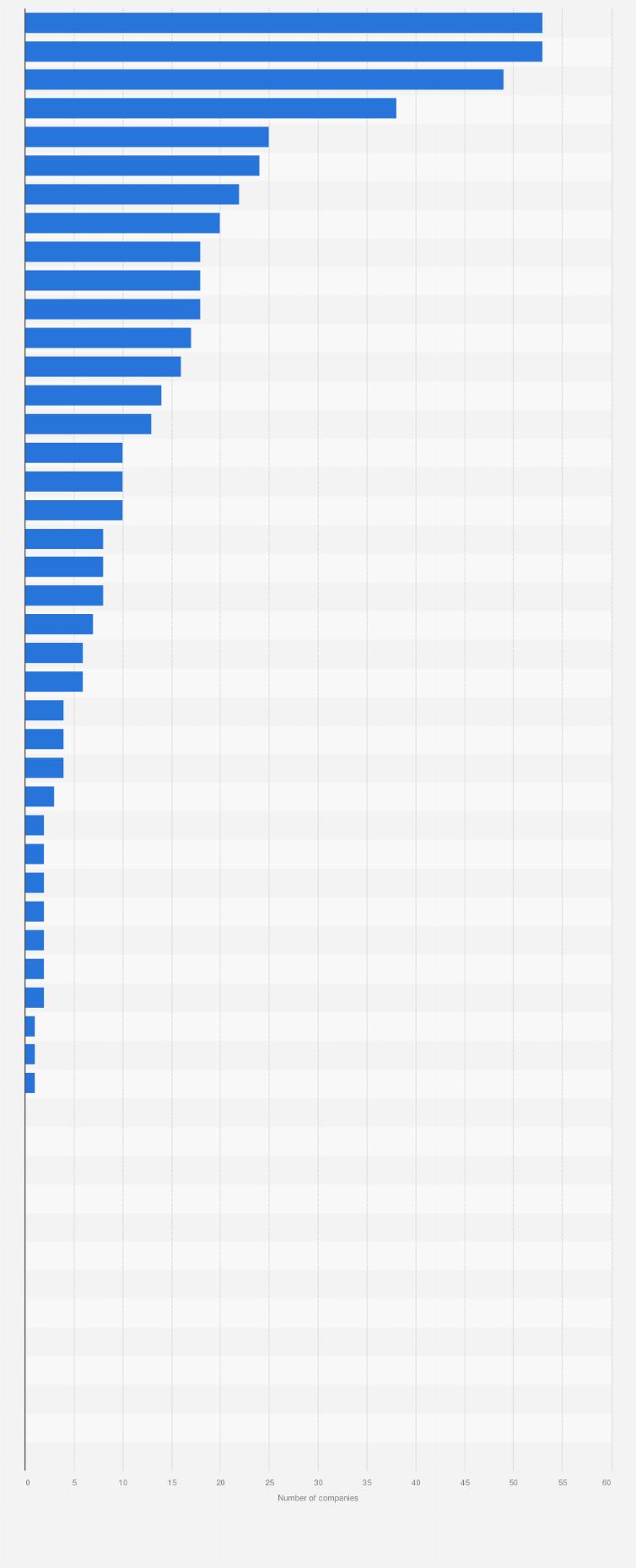

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action, which increases efficiency. Sorting things makes it easier to find them later. When items are ordered, they are put together. You then organize your inventory in groups. Finally, when you label your containers, you ensure everything is labeled correctly.

Employees need to reflect on how they do their jobs. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. They will need to develop new skills and techniques in order for the 5S system to be implemented.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They are more motivated to achieve higher efficiency levels as they start to see improvement.