Six-Sigma and lean are complementary approaches to improving processes. Both tools can be used to solve problems but each approach has its own strengths. Six Sigma is a statistical process control technique. Lean starts with Lean's premise that a product must provide value, not just create it. Lean's key principle is to eliminate waste while improving the product's quality.

Problem solving in PDCA

Although there are some differences between DMAIC problem-solving and PDCA (problem solving), both are based upon the DMAIC approach. Planning and analysis is required to complete the PDCA process. PDCA, unlike DMAIC is not effective in solving urgent problems. This approach requires a problem solver with technical skills. Six Sigma will require a problem-solving team lead who is a Six Sigma "green belt" certified practitioner.

In Six Sigma, problem-solving follows a cycle that was first introduced in the 1950s by W. Edwards Deming. Its creators intended to use it in conjunction with continuous improvement methods to help rebuild Japan's industries. The P (Plan) stage requires real data to be gathered and a clear mission. After the PDCA stage, the group must choose a solution.

Process maps

There is one key difference between Six Sigma process maps and Lean. It's how each method describes the processes. While both methods emphasize the importance of defining a process clearly, each method focuses on different aspects. Lean, for instance, involves mapping actual processes as opposed to standard operating procedures. Consider major decisions and approval sources when creating process maps. Include areas that require multiple methods and factors. Make sure you match the roles and look at the process flow.

To show the flow of a process, a process map should contain steps, symbols and arrows. To ensure that each process accurately depicts the actual process, several people should review it. A process map should also include the date of its creation and contact information for any questions. Process maps can be a great way to improve any process. They may also be complex.

Analysis of cause and effect

Six Sigma, lean project management techniques are based on statistical analysis. The Cause and Effect Matrix is a way to link the steps in a process with their outputs and inputs. The customer's requirements will be listed in the order that they are most important. Inputs, outputs, and their impact on the outcome are ranked. The ranking and key input variables should be established.

Although each technique may have its own set of benefits they are not all the same. Lean Six Sigma uses a process management methodology that is based around Frederick Winslow Taylor’s Principles of Scientific Management. Taylor envisioned business processes as interlocking processes and workflows. He also recommended reducing variation. In the process of reducing waste, Six-Sigma and lean are complementary.

Elimination of variation

Variability is part of every manufacturing process. This variability can create uncertainty in the result. Professional results require consistency. Predictable output is achieved by eliminating variation in Six Sigma and Lean manufacturing processes. Some amount of variation is fine, but too much leads to repairs, rework, and possibly even out-of-business consequences. It is important to determine the root causes of variation in order to address it.

The first place to look for variations is at decision points. Process maps identify decision points, which are represented by diamonds. Six Sigma teams can begin by identifying decision points, and then start eliminating variations. This information can be obtained from the Six Sigma team or the process owner. The Six Sigma team will not be able to focus if the process owner does not follow a standard procedure. This is why a Six Sigma team must have the technical capabilities to adjust the process map.

FAQ

How can manufacturing excess production be decreased?

The key to reducing overproduction lies in developing better ways to manage inventory. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. This would allow us to use our resources for more productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board, a visual display to show the progress of work, is called a Kanban board. A Kanban system allows work items to move through several states before reaching their final destination. Each state is assigned a different priority.

When work is completed, it can be transferred to the next stage. It is possible to keep a task in the beginning stages until it gets to the end.

This keeps work moving and ensures no work is lost. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing is another option to control inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. This is accomplished by forecasting the demand and identifying production resources.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

Why automate your warehouse?

Modern warehousing is becoming more automated. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. To do so, they must invest heavily in technology. The benefits of automating warehouses are numerous. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety enhancements

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

This ensures that quality products are delivered promptly

-

Eliminates human error

-

It helps ensure compliance with regulations

What are the jobs in logistics?

There are different kinds of jobs available in logistics. Here are some examples:

-

Warehouse workers - They load trucks and pallets.

-

Transportation drivers – They drive trucks or trailers to transport goods and perform pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Other - Logistics has many other job opportunities, including transportation supervisors, logistics specialists, and cargo specialists.

What is the role of a manager in manufacturing?

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should be alert for any potential problems in the company and react accordingly.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

What is the responsibility of a logistics manager?

A logistics manager ensures that all goods are delivered on time and without damage. This is accomplished by using the experience and knowledge gained from working with company products. He/she must also ensure sufficient stock to meet the demand.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

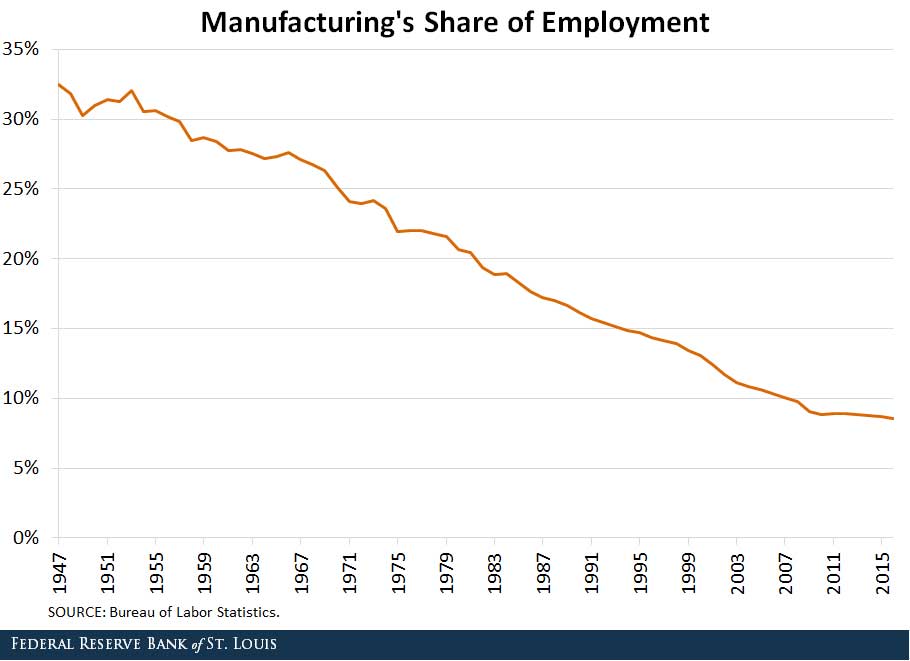

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use Just-In-Time Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It allows you to get the right amount resources at the right time. This means that your only pay for the resources you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. Taylor observed that overtime was paid to workers if they were late in working. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will allow you to track how much material you have left over after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This is a type where you stock the materials required for your projects in advance. This allows you to forecast how much you will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT is the most widespread form. This is where you assign resources based upon demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If there aren't many orders, you will assign fewer people.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It's used when you want to maximize production while minimizing inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important as it reduces leadtimes and increases throughput.