Whether you are running a large corporation or a small business, supply chain management software can help you streamline your processes and improve your efficiency. These systems can give you a central view to your entire supply network, allowing for planning production, shipment planning, as well as delivery routes. These systems allow you to automate and streamline your processes, allowing your employees to concentrate on other aspects of the business. Every company that is responsible for shipping and manufacturing should have supply chain software.

You should consider several capabilities and features when choosing the right supply chain management software. These include scalability. ease of use. And integration with other programs. It is also important to evaluate the reputation of the provider as well as the features available. You should also consider your budget when choosing a solution. Whether you choose a full-scale package or a SaaS solution, make sure you can adapt to your needs as your business grows.

E2open is a leader in supply chain management software, specialising in cloud-based services that deliver better demand forecasting as well as operations management. E2open also provides advanced features and a technology platform. Software is available for businesses in many industries including manufacturing, retail, and transportation.

Supply chain management software has a key feature: real-time visibility. This software allows you to track and monitor your inventory as well as your shipments. It will help you make sure your customers have what is needed when they want it. It allows you to create long-term plans for managing demand-supply imbalance.

Kinaxis is an integrated supply chain management software tool that reduces silos and streamlines operations. It combines human-machine intelligence to enable you to make better decision. It can also assist you in planning inventory and capacity so that you can better react to opportunities.

This software can be used to forecast sales and helps you understand historical sales cycles and seasonality. Machine learning is also used to predict sales. This software predicts sales and helps to prepare sales teams for the future. You also have access to data from multiple sources so you can see the whole picture of your business.

Descartes Systems Group, the biggest competitor to supply-chain management software, is their main competitor. They are the most preferred vendor for many organizations. The company boasts over 13,000 users and competes with SAP SCM and Megaventory as well as JDA and Logility.

Another major competitor to supply chain management software is Manhattan Associates. This software company boasts thousands of users and a revenue of approximately $617.5million. Eddie Capel is the current owner. This company competes against JDA, Logility, and Infor SCM.

Infor SCM is a top-rated supply chain management platform. It's ideal for all businesses and is one of the most well-known supply chain management software solutions. It is cloud-based and unites all aspects of enterprise operations. It also includes analytics at the core, which can help you optimize your end-to-end supply chain.

FAQ

What is the responsibility of a manufacturing manager?

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should also be aware of any problems within the company and act accordingly.

They must also be able to communicate with sales and marketing departments.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Why is logistics so important in manufacturing?

Logistics are an essential part of any business. They are essential to any business's success.

Logistics plays a significant role in reducing cost and increasing efficiency.

Can some manufacturing processes be automated?

Yes! Since ancient times, automation has been in existence. The Egyptians discovered the wheel thousands and years ago. We now use robots to help us with assembly lines.

In fact, there are several applications of robotics in manufacturing today. They include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation can be applied to manufacturing in many other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Is automation important in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It allows them to offer services faster and more efficiently. In addition, it helps them reduce costs by reducing human errors and improving productivity.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. Understanding the manufacturing process will allow you to better understand logistics.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

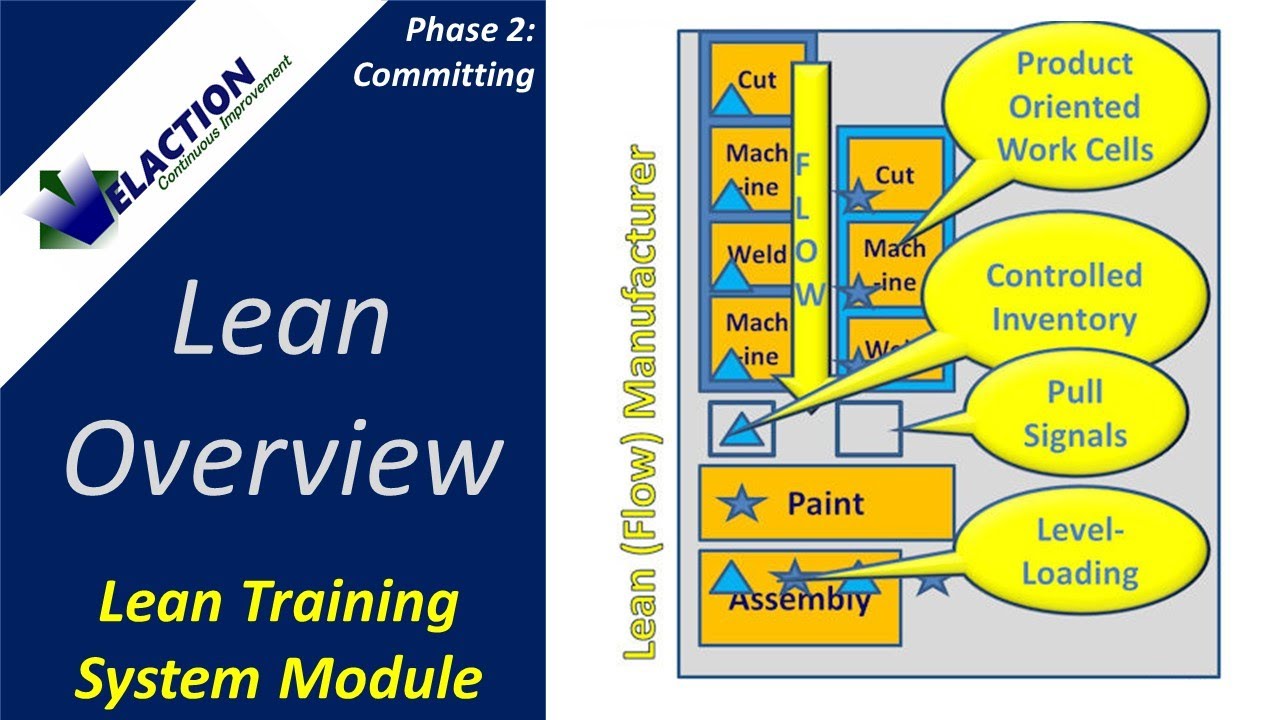

How to Use the Just In Time Method in Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. This is where you have the right resources at the right time. This means that your only pay for the resources you actually use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. Taylor observed that overtime was paid to workers if they were late in working. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You can anticipate problems and have enough equipment and people available to fix them. This way, you won't end up paying extra money for things that weren't really necessary.

There are many types of JIT methods.

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will allow you to track how much material you have left over after using it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based : You can stock the materials you need in advance. This allows one to predict how much they will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT: This is the most popular form of JIT. Here you can allocate certain resources based purely on demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If there aren't many orders, you will assign fewer people.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This is very similar to cost-based but instead of looking at total costs of the company you are concerned with how many raw materials you use on an average.

-

Time-based: Another variation of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your goal is to add value to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It's useful when you want maximum production and minimal inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. This is important as it reduces lead time and increases throughput.