The Great Recession saw 166,000 jobs being lost by Ohio manufacturing companies. The recovery of Ohio's manufacturing industry has been slow. Ohio's manufacturing job opportunities are still lower than they were prior to the recession.

Ohio's manufacturing jobs have declined due to increased competition from Europe and Japan. Manufacturers have been forced to become technologically more advanced and shed labor costs. The global economic climate is lukewarm which has led to job loss.

Ohio's current workforce crisis is a significant challenge for manufacturers. There are many initiatives that can be taken to address the state's skilled labor shortage. These initiatives are fragmented and siloed and don't address all the workforce issues manufacturers face. The Ohio Governor's Office of Workforce Transformation issued a special report on the workforce shortage, which recommended better collaboration between educators and businesses. However, it found that there was a disconnect between business needs and the school curriculum.

Ohio's workforce is multifaceted, complex and diverse. Workers in manufacturing are less likely than those in other industries to be represented in a union. But unionized manufacturing jobs still offer solid benefits and livable wage.

Ohio's manufacturing sector contributes significantly to its economy. Interstate highways, railroads, and inland waters allow manufacturers to transport goods at a low cost. The state is also a leading exporter. The state also produces natural gaz, which is a big draw for private investors.

Although the state has reclaimed 50,000 manufacturing jobs in the past four years, Kasich's first term was marked by slow job growth. In Kasich's first three terms, the average manufacturing job gain was 7 percent. Manufacturing jobs have dropped by 1,771 jobs in the last two years. These losses are caused by the slowing economy, the automobile industry, and lukewarm global demands.

Ohio is a major exporter of goods. It has top export markets such as the U.S., Canada and Mexico. However, exports have fallen by $1.4 million in the last year. Ohio manufacturers continue to face a major problem with trade policy. While trade policy changes may be helpful to certain workers, they will not address the whole range of problems.

Manufacturing is still one of Ohio's most important industries. Manufacturing jobs are the highest-paid jobs for semi-skilled workers with no post-secondary education. But wages in Ohio have not kept pace with the production. Manufacturing jobs pay more in Ohio than any other industry, but they are not sufficient for middle-class lifestyles.

Ohio's manufacturing workforce consists of a diverse group of workers. The state's manufacturing industries have been diversifying to match the rest of the nation. Ohio has become more service-oriented and manufacturing is no longer Ohio’s main employer. Manufacturers now focus more on international exposure, and developing skills for the future.

FAQ

What is production management?

Production Planning includes planning for all aspects related to production. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to decide what you want. You may have decided where to shoot or even specific locations you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

After you have chosen the right car, you will be able to begin thinking about accessories. Do you have people who need to be seated in the front seat? You might also need someone to help you get around the back. Perhaps you would like to change the interior colour from black to white. These questions will help determine the look and feel you want for your car. You can also think about the type of shots you want to get. Will you be filming close-ups or wide angles? Maybe you want the engine or the steering wheels to be shown. These things will help you to identify the car that you are looking for.

Once you have all the information, you are ready to create a plan. You will know when you should start and when you should finish shooting. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. It will help everyone know exactly what they have to do and when. You can also make sure to book extra staff in advance if you have to hire them. It is not worth hiring someone who won’t show up because you didn’t tell him.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects are quick and easy, while others take weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. However, you shouldn't overestimate the amount of money you will spend. You will end up spending less money if you underestimate the cost of something.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

How is a production manager different from a producer planner?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

What is the job of a production plan?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. A production planner ensures that the service and product meet the client's expectations.

What does warehouse mean?

Warehouses and storage facilities are where goods are kept before being sold. You can have it indoors or outdoors. It could be one or both.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

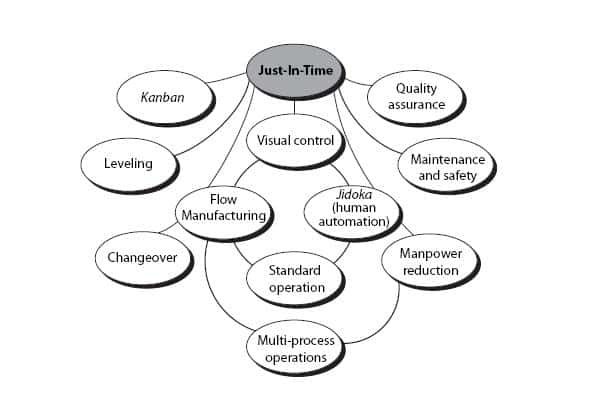

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes eliminating waste and defects throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing is widely used in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. To increase their competitiveness, many businesses have turned to lean manufacturing. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT means that components are assembled at the time of use and not manufactured in advance. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. It involves continuous improvement of processes, people, and tools.